Crafting Kitchens That Stand the Test of Time

When it comes to designing and remodeling a kitchen, one of the most significant investments you’ll make is in your cabinetry. Quality kitchen cabinets and drawer boxes not only enhance the aesthetics of your kitchen but also ensure functionality and long term durability. Here’s a comprehensive guide to understanding the components that make up high-quality kitchen cabinets and drawer boxes.

1. Material Options

The materials used in constructing kitchen cabinets and drawer boxes play a critical role in their durability and appearance. Solid wood, such as oak, maple, cherry, and walnut, is a top choice for its unmatched durability and natural beauty, capable of being refinished over time to maintain its look. Plywood is another excellent option, known for its strength and resistance to moisture compared to particleboard. Made from layers of wood veneer glued together, plywood is less prone to warping or shrinking and is lighter, making it easier to handle during installation. MDF (Medium-Density Fiberboard) offers a smooth surface ideal for painting and is crafted from wood fibers glued under high pressure and temperature. While not as strong as plywood, MDF is perfect for areas where a flawless finish is desired. Choosing high-quality materials ensures that your kitchen cabinets and drawer boxes will stand the test of time, providing both beauty and functionality.

Solid Wood:

Solid wood is often the gold standard for kitchen cabinet doors, face frames, and drawer boxes. It offers unmatched durability, a classic look, and the ability to be refinished over time. Common woods used include hickory, oak, maple, cherry, and walnut, each offering unique grain patterns and colors. The natural beauty of solid wood can add a warm, timeless appeal to any kitchen.

Plywood:

Plywood is the most popular choice for the cabinet box, known for its strength and resistance to moisture compared to particleboard. Made from layers of wood veneer glued together, plywood is less likely to warp or shrink. It’s also lighter than particle board, making it easier to handle during installation.

Particleboard:

Particleboard is a wood based product manufactured using wood particles mixed with adhesives, heated and compressed into a sheet. Particleboard is often regarded as a “cheap” and undesirable component in kitchen cabinetry, but that opinion may not always be correct. Just like plywood, there are all different grades and densities of particleboard; depending on the use and application, it may be a fine material in your cabinetry. Be sure your understanding the construction or consult a reliable Cabinet Specialist.

MDF (Medium-Density Fiberboard) & HDF (High Density Fiberboard):

MDF & HDF are man-made materials that provide a smooth surface, ideal for painting. It’s made from wood fibers glued under high pressure and temperature. While not as strong as plywood, MDF & HDF are good choices for areas where a smooth finish is desired, such as painted cabinet doors.

2. durable Joinery

The joinery method used in kitchen cabinets and drawer boxes is crucial for their strength and longevity. Dovetail joints are a hallmark of quality, providing robust interlocking connections, especially for drawers. Mortise and tenon joints are another classic method, offering exceptional strength and durability for frame construction. Dado and rabbet joints, which involve cutting grooves and recesses into the wood, create secure connections for shelves and back panels. These traditional joinery techniques ensure that the cabinets can withstand daily use and remain stable over time, contributing to the overall durability and functionality of your kitchen cabinetry

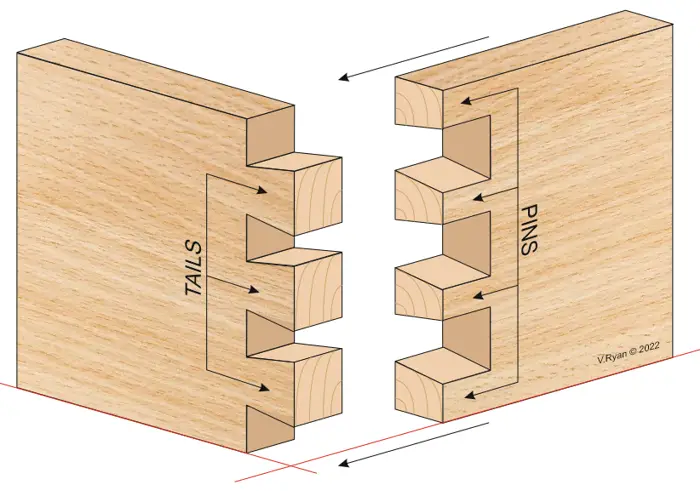

Dovetail Joints:

Dovetail joints are a hallmark of high-quality drawer boxes. The interlocking wedge-shaped cuts provide a strong connection that resists being pulled apart. This type of joint is not only functional but also adds a touch of craftsmanship to your cabinets.

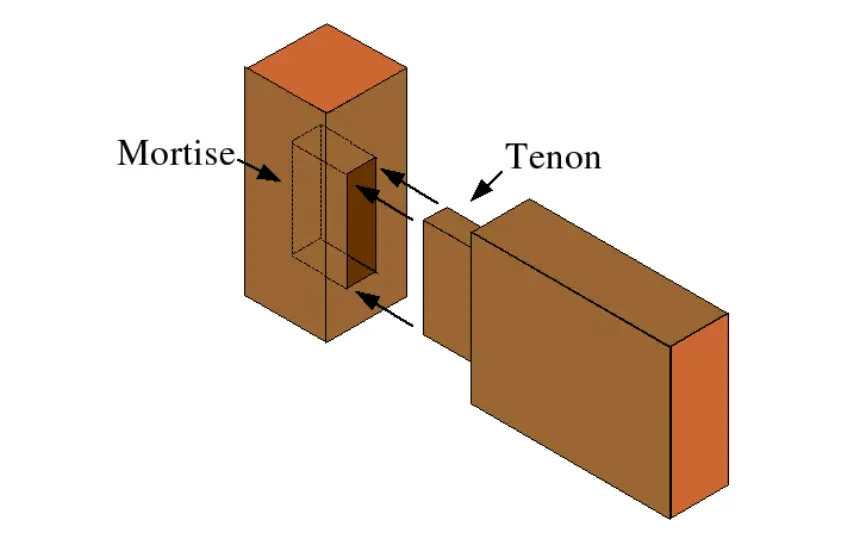

Mortise and Tenon Joints:

This classic joinery method involves fitting a tenon (a projection) into a mortise (a cavity) to create a strong, durable connection. Mortise and tenon joints are commonly used in face frame construction and are valued for their

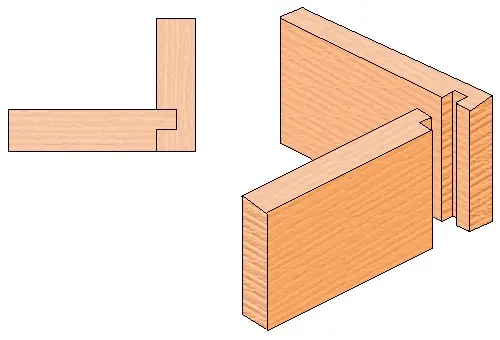

Dado and Rabbet Joints:

These joints involve cutting grooves into the wood to fit another piece into it, creating a strong connection for shelves and back panels. Dado joints run across the grain, while rabbet joints are cut along the edge of the wood. Both provide additional support and stability.

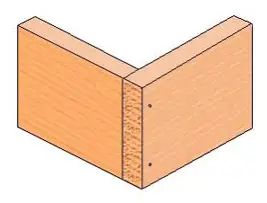

lap Joints and butt joints:

These two joints are the least complex, and also the weakest. These joints should be avoided in high use items such as drawer boxs. Less expensive drawer boxs will often have these simpler jointing methods. Although the price-point may be appealing, these will NOT hold up for very long.

3. Quality Hardware

Soft-Close Hinges:

Soft-close hinges are essential for modern kitchen cabinets, preventing doors from slamming shut. These hinges ensure smooth, quiet closing, reducing wear and tear on the cabinets and adding a touch of luxury.

Full-Extension Drawer Slides:

Full-extension drawer slides allow you to access the entire drawer, making it easier to reach items stored at the back. They provide a smoother, more efficient operation compared to partial extension slides.

Quality Handles and Knobs:

Handles and knobs are not just functional but also contribute to the overall look of your kitchen. High-quality hardware is durable and comfortable to use. Options range from sleek, modern designs to more traditional styles, allowing you to personalize the look of your cabinets. Keep in mind, hardware is the jewelry for the cabinetry, have fun with it.

4. Finish

High-Quality Paint or Stain:

The finish on your cabinets protects the wood and enhances its appearance. High-quality paints and stains provide a smooth, attractive finish that can withstand the daily wear and tear of kitchen use. The finish should be resistant to moisture, heat, and cleaning agents.

UV-Cured Finish:

A UV-cured finish is highly durable and resistant to scratches and yellowing. This type of finish is applied in a controlled environment and cured using ultraviolet light, resulting in a hard, protective coating.

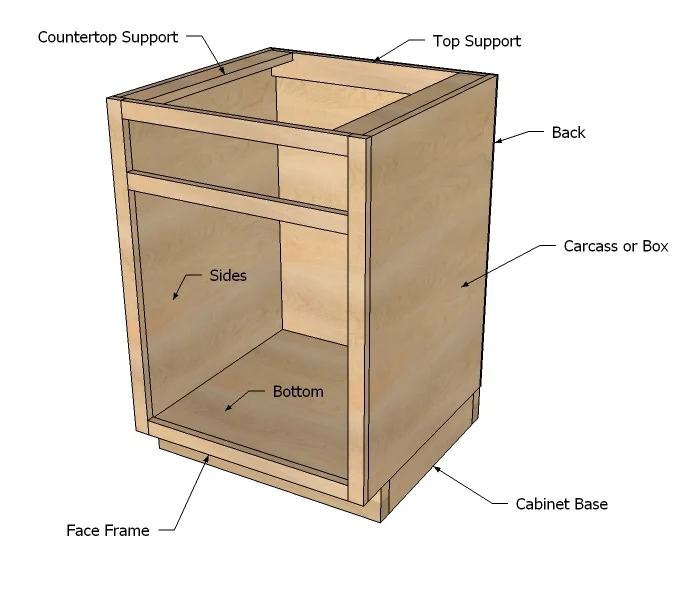

5. Box Constuction

Solid Back Panels:

A solid back panel adds stability and support to your cabinets. It helps keep the cabinet square and provides a secure surface for mounting the cabinet to the wall. Plywood or MDF are commonly used for back panels, with plywood being the more durable option.

Solid Back Panels:

A solid back panel adds stability and support to your cabinets. It helps keep the cabinet square and provides a secure surface for mounting the cabinet to the wall. Plywood or MDF are commonly used for back panels, with plywood being the more durable option.

Reinforced Corners:

Reinforced corners enhance the structural integrity of the cabinet box. Corner blocks or braces are added to the corners of the cabinet, providing additional strength and preventing the box from racking or twisting.

6. Shelves

Adjustable Shelving:

Adjustable shelves allow you to customize the storage space inside your cabinets. This feature is especially useful for accommodating items of different heights and maximizing storage efficiency. Look for cabinets with sturdy shelf supports that can hold heavy items without sagging.

Thick, Sturdy Shelves:

Shelves should be thick enough to support the weight of stored items without bending or sagging; typically 5/8″ is a minimum standard, 3/4″ is highly recommended. Plywood or solid wood shelves offer superior strength opposed to particleboard which may sag under weight and over time.

7. Face Frames

Solid Wood Frames:

Face frames made from solid wood provide strength and stability to traditional-style cabinets. The frame is attached to the front of the cabinet box and provides a mounting surface for doors and drawers. Common woods used for face frames include maple, hickory, walnut, oak, and cherry.

Solid Bottom Panels:

The bottom panel of the drawer should be solid and sturdy to prevent sagging under the weight of stored items. Plywood in a thickness of 1/4″ to 1/2″ is an excellent choice for drawer bottoms due to its strength and resistance to warping, avoid pressboard and furniture-board.

8. Drawer Box Construction

Thick Drawer Sides:

High-quality drawer boxes have sides that are typically 1/2″ inch or thicker. Thicker sides provide greater durability and are less likely to warp or crack over time. Solid wood or plywood is preferred for drawer sides due to their strength, avoid particleboard and furniture-board. Dovetail corners are imperative for long term durability; drawers are asked to hold a lot of weight and are used constantly.

Solid Bottom Panels:

The bottom panel of the drawer should be solid and sturdy to prevent sagging under the weight of stored items. Plywood in a thickness of 1/4″ to 1/2″ is an excellent choice for drawer bottoms due to its strength and resistance to warping, avoid pressboard and furniture-board.

9. Installation

Proper Leveling and Securing:

Proper installation is crucial to the performance and longevity of your cabinets. Cabinets should be level and securely attached to the wall to prevent shifting and ensure doors and drawers operate smoothly. Professional installation ensures that cabinets are aligned correctly and securely fastened. Regardless of the quality of the cabinet, improper installation most often results in product failure.

10. quality design

Quality Design Expertise:

Having a relationship with a trusted Kitchen Designer will ensure you receive the most value from your new kitchen cabinetry. A professional Kitchen Designer can help you understand the different material and construction options and where they make the most impact, so you can get the quality you are looking for, without overspending unnecessarily. The layout and design of the kitchen is another critical aspect, best left to a professional. A designer may suggest plywood ends for all the exposed cabinet sides, but perhaps particleboard for all the concealed sides, giving you quality where it matters most. A skilled designer should be able to work within a stock cabinet line creatively so you get a very Custom look without the Custom price. Regardless of what “brand” of cabinets you decide to purchase, hiring a Design Professional can make all the difference!

The Importance of Investing in High-Quality Kitchen Cabinets and Drawer Boxes

Investing in high-quality kitchen cabinets and drawer boxes can significantly enhance the functionality and aesthetics of your kitchen. By paying attention to the materials used, construction methods, hardware, finishes, and installation, you can ensure that your cabinets will stand the test of time and provide years of reliable service. Whether you’re renovating an existing kitchen or building a new one, understanding these key components will help you make informed decisions and achieve the kitchen of your dreams.